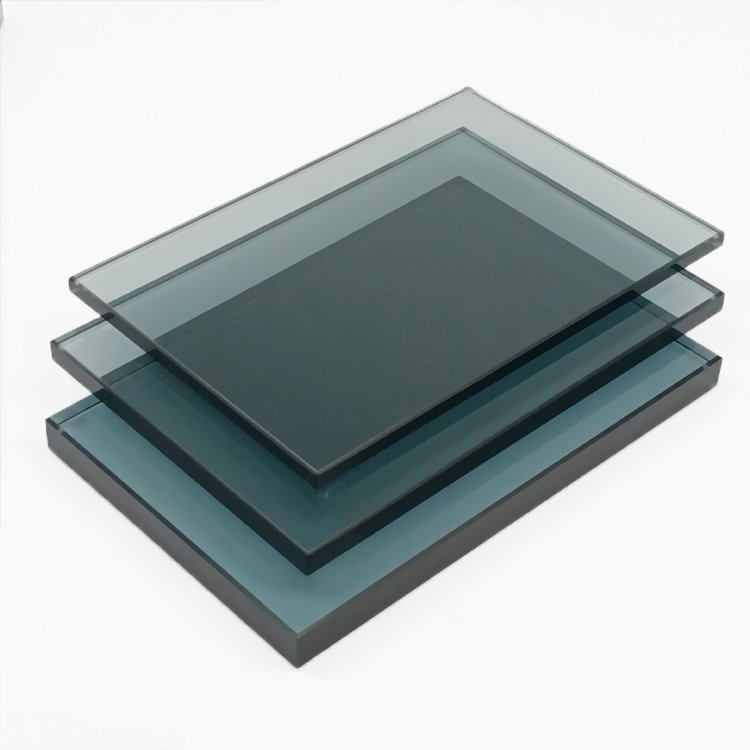

What is Heat Strengthened Glass?

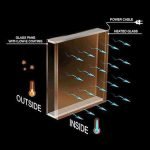

Heat Strengthened Glass is a type between ordinary flat glass and tempered glass, also known as heat-strengthened glass. It is made by annealing glass and subjecting it to high temperature and quenching treatment, forming a compressive stress of less than 69MPa on the surface, which increases the mechanical strength of the glass several times. It should be noted that a single piece of Heat Strengthened Glass is not a safety glass, because once it is broken, it will form large fragments and radial cracks. Although there are no sharp fragments, there is a certain possibility of injury.

Characteristics of Heat Strengthened Glass

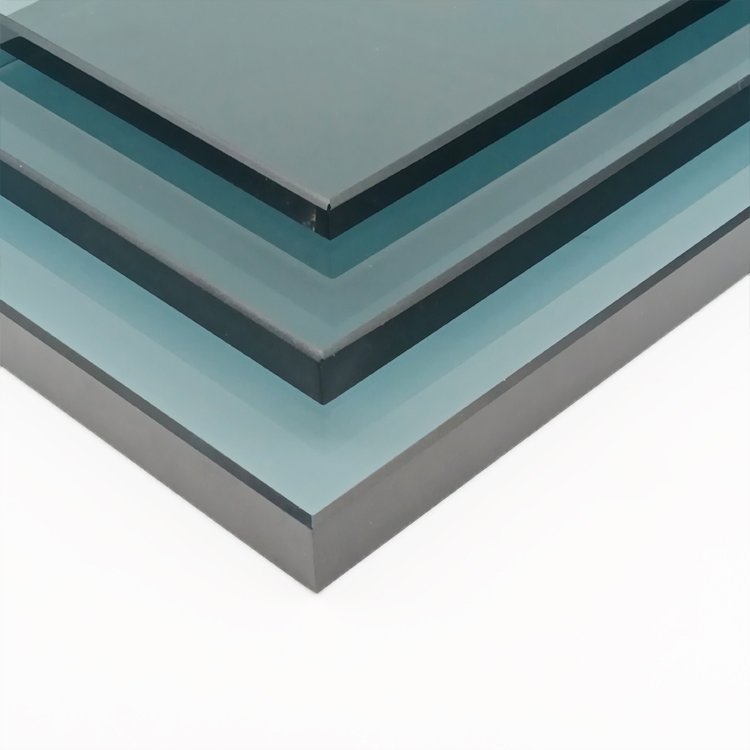

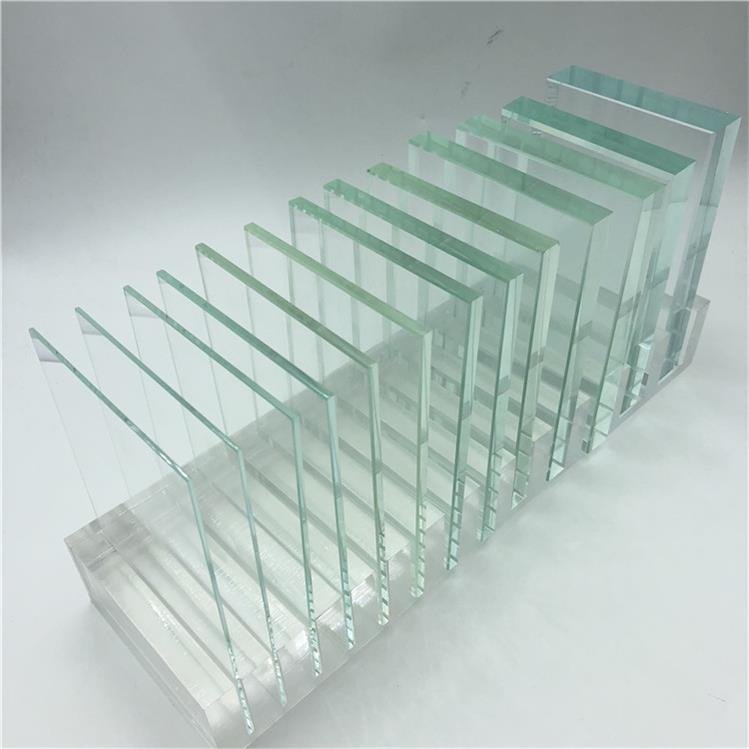

- Improved strength: The strength of Heat Strengthened Glass is more than twice that of ordinary float glass. This enhancement is achieved by forming a compressive stress of less than 69 MPa on the surface of annealed glass during high temperature and quenching.

- Higher safety: Although Heat Strengthened Glass is not a safety glass, its fragments are radial when it breaks and each fragment extends to the edge, which is not easy to fall off, making it safer than ordinary glass. However, its fragments may still injure people, so it cannot be used in skylights and occasions where human impact may occur.

- Good thermal stability: The thermal stability of semi-tempered glass is significantly better than that of ordinary annealed glass, and it can withstand a temperature difference of about 75°C. In contrast, the temperature difference that ordinary glass can withstand after tempering is about 180°C.

- Not easy to explode: Unlike tempered glass, semi-tempered glass will not explode.

- Better flatness: Compared with tempered glass, semi-tempered glass has better flatness and is closer to ordinary annealed glass

Applications of Heat Strengthened Glass

- Modern architectural design: Heat Strengthened Glass has become the preferred material for modern architectural design due to its safety and heat insulation performance.

- Automobile manufacturing: Heat Strengthened Glass is used in the design of vehicle side windows and rear windows to improve impact resistance and safety.

- Home appliance field: Semi-tempered glass is used as the facade material of kitchen appliances, which is heat-resistant, transparent and easy to clean.

- Home decoration: Semi-tempered glass shows excellent physical properties in furniture, doors and windows, and shower partitions.

- Solar panels: Use heat-tempered glass to improve light transmittance and photoelectric conversion efficiency.

- Greenhouse: Use the high light transmittance and stability of semi-tempered glass to ensure that plants get sufficient light and adapt to harsh environments.

To learn more about our products, please visit https://trustmyglass.com/products

In summary, Heat Strengthened Glass has become one of the preferred materials in all walks of life due to its excellent performance and wide application fields. With the continuous advancement of science and technology and the changes in development needs, it is believed that heat-strengthened glass will be applied and developed in more fields.