What is Heat Soak Tempered glass?

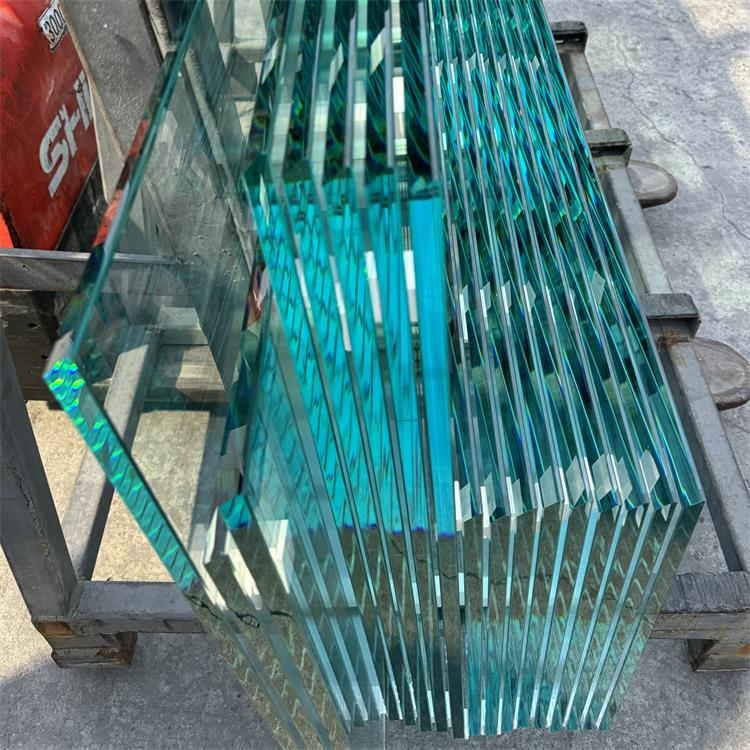

Heat Soak Tempered glass, also known as homogenized glass or heat-dip tempered glass, is a type of tempered glass that has been treated through a specific process. This treatment process is called heat-dip treatment, which aims to reduce the spontaneous explosion of tempered glass during use. The specific process is to heat the tempered glass to about 290℃±10℃ and keep it warm for a certain period of time to prompt nickel sulfide to quickly complete the crystal phase transformation in the tempered glass. Nickel sulfide is one of the main causes of tempered glass spontaneous explosion.

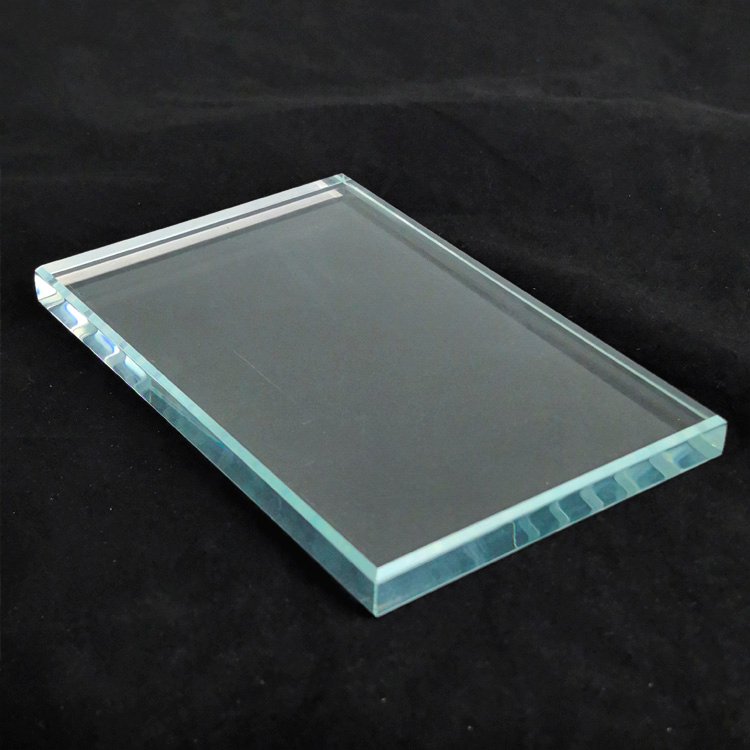

Characteristics of Heat Soak Tempered glass

- Reduce the self-explosion rate: Hot-dip treatment is a method to reduce the risk of self-explosion of tempered glass by heating and heat preservation. It can promote the rapid crystal phase transformation of nickel sulfide in tempered glass, thereby reducing the self-explosion phenomenon during use after installation.

- Improve safety: Even if the tempered glass treated by hot-dip treatment is broken, it will form small and blunt fragments, reducing the risk of injury to the human body.

- Beautiful and practical: The curved surface of the heat-soaked glass has no joints in the middle, and the lines are beautiful visually, which can achieve an overall harmonious situation and meet functional requirements.

- Reduce maintenance costs: Due to the low self-explosion rate of hot-dip glass, the replacement and maintenance costs caused by self-explosion are reduced.

Applications of Heat Soak Tempered glass

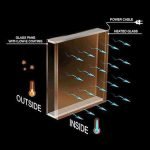

- High-rise building curtain walls: Heat-soaked glass is used to make curtain walls in high-rise buildings, providing good visual permeability and wind pressure resistance.

- Display cabinets: Heat Soak Tempered glass can also be used to make display cabinets, which not only protects exhibits but also facilitates viewing by the audience.

- Explosion-proof glass: In some special occasions, such as laboratories, military facilities, etc., a higher level of security protection may be required. Heat-soaked glass can be made into explosion-proof glass through further processing.

- Fire-proof glass: Heat Soak Tempered glass can also be compounded with other materials to make glass with fire-proof properties for fire doors, firewalls, etc.

- Indoor partitions: Due to its high strength and safety, Heat Soak Tempered glass is often used as an indoor partition material, which is both beautiful and practical.

- Door and window manufacturing: The high impact resistance of Heat Soak Tempered glass makes it an ideal material for door and window manufacturing, which can resist external impact and improve the safety of buildings.

To learn more about our products, please visit https://trustmyglass.com/products

In general, Heat Soak Tempered glass is widely used in many fields such as construction, automobiles, and home appliances due to its unique physical properties and safety. When choosing to use it, you need to choose the appropriate type and specification according to specific needs and application scenarios.