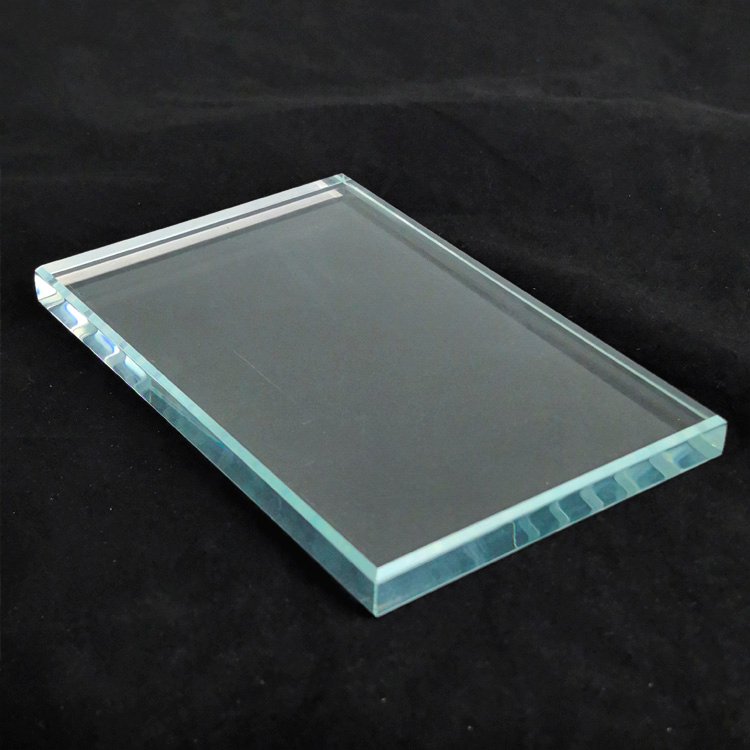

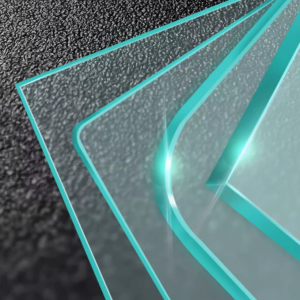

What is Clear float glass?

clear float glass is a type of flat glass with many excellent properties. It is widely used in modern architecture, automobiles, solar energy and other fields. The prepared raw materials are heated at high temperature to form a uniform, pure and transparent glass liquid, which then flows continuously from the tank kiln and floats on the surface of the relatively dense tin liquid. Under the action of gravity and surface tension, the glass liquid spreads and flattens on the tin liquid surface to form a glass ribbon with uniform thickness and smooth upper and lower surfaces. Then the annealing and cutting steps are carried out.

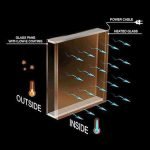

Technology Behind Clear Float Glass

- Raw material selection: sea sand, quartz sandstone powder, soda ash, dolomite, etc. are used as the main raw materials. These raw materials are strictly screened and proportioned to ensure the quality and performance of the glass.

- Melting process: The raw materials are mixed and sent to the glass tank kiln for high-temperature melting. The temperature in the tank kiln usually reaches above 1500℃, so that the raw materials are fully melted into uniform glass liquid. This process requires strict control of temperature and time to ensure the quality and uniformity of the glass liquid.

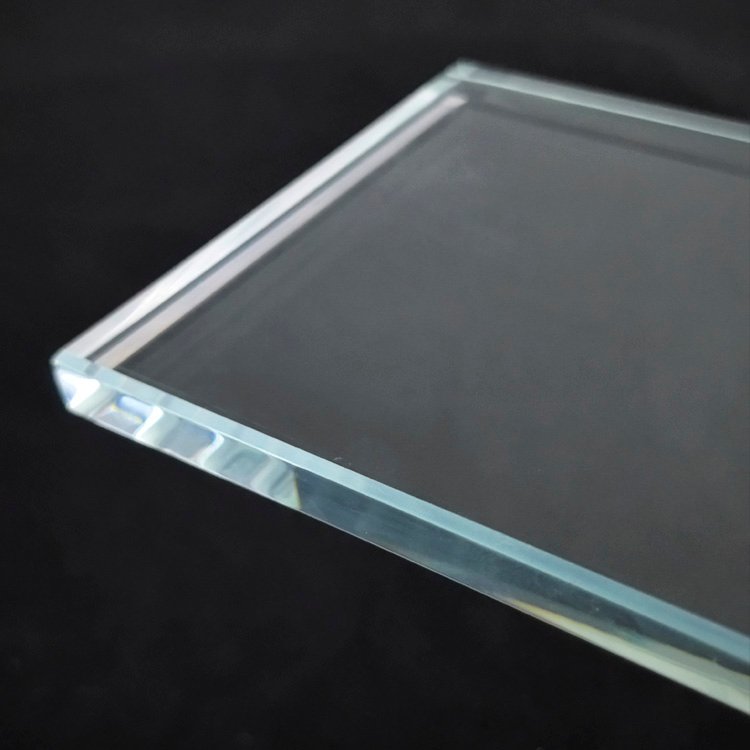

- Floating molding: The molten glass liquid flows smoothly and continuously into the tin bath through the flow channel under the control of the regulating gate. Since the density of glass is only about 1/3 of the density of tin liquid, it floats on the surface of the tin liquid.

- Edge pulling control: The glass ribbon is pulled and controlled by the edge pulling machine to achieve the required thickness and width. At the same time, the thickness and shape of the glass ribbon can be changed by adjusting the speed and angle of the edge pulling machine.

- Cooling annealing: After the glass ribbon leaves the tin bath, it enters the annealing kiln for preliminary cooling. In this process, the glass ribbon gradually cools down and shrinks to eliminate internal stress.

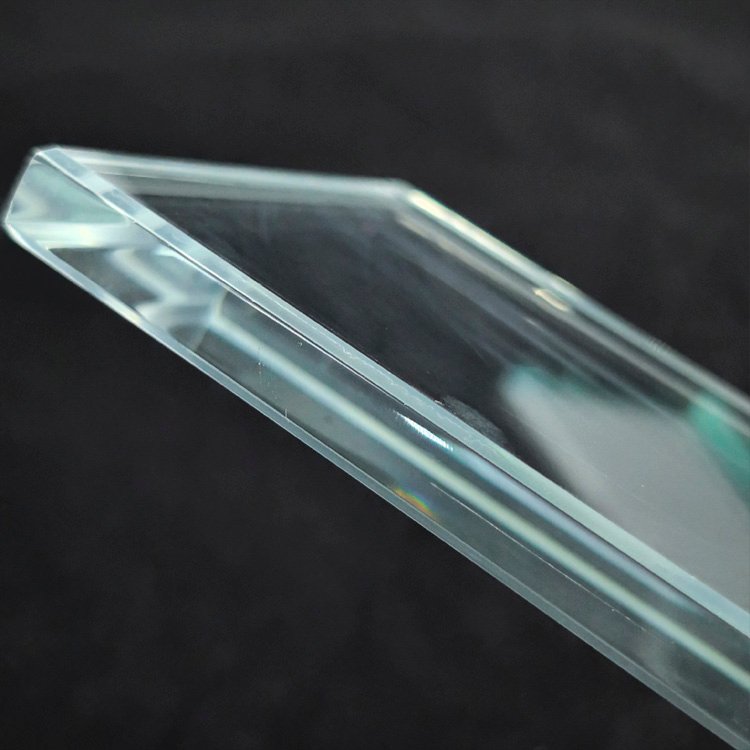

- Tempered treatment: If needed, the glass strip can also be tempered to improve its strength and safety. Tempered glass has higher impact resistance and bending resistance.

Advantages of Clear Float Glass

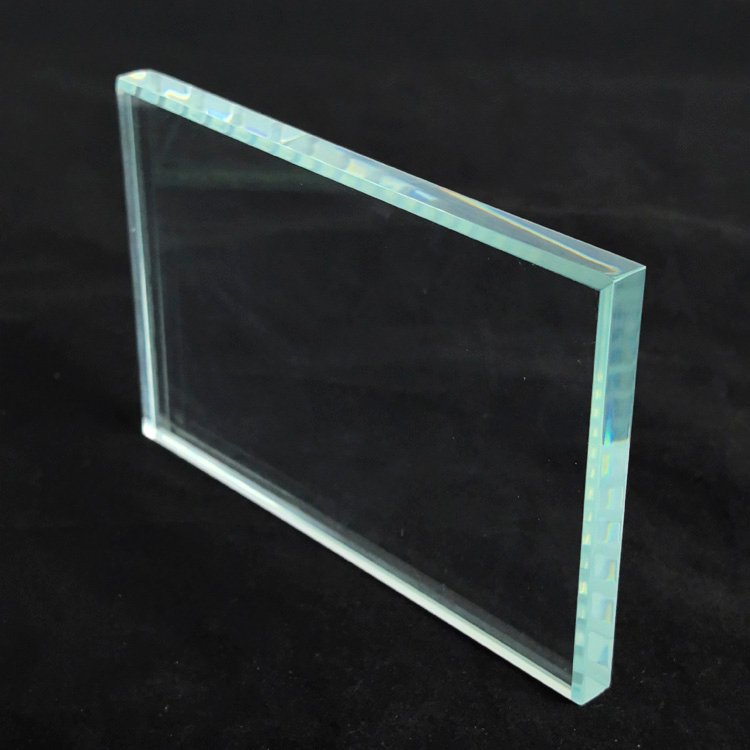

- High Clarity and Transparency:One of the most significant advantages of float glass is its exceptional clarity and transparency. This property makes it ideal for applications where visibility is paramount, such as windows and display cases.

- Uniform Thickness:The float glass process ensures uniform thickness across the sheet, making it easier to handle and install. This consistency is essential for maintaining structural integrity in construction and design.

- Versatility:Clear float glass can be treated and processed in various ways, including coating, laminating, and tempering. This versatility allows it to be adapted for different uses, from safety glass to decorative applications.

- UV Protection:Certain treatments can enhance clear float glass’s ability to block harmful UV rays, protecting interior furnishings and reducing energy costs by minimizing heat gain.

- Eco-Friendly:Float glass is recyclable, which makes it an environmentally friendly option. The recycling process is efficient and helps reduce the demand for raw materials.

4.Applications of Clear Float Glass

- Construction:float glass is extensively used in residential and commercial buildings for windows, facades, and skylights. Its clarity allows natural light to permeate indoor spaces while providing thermal insulation and sound reduction.

- Automotive Industry:In the automotive sector, clear float glass is used for windshields, side windows, and rear windows. Its strength and clarity contribute to safety and aesthetic appeal.

- Furniture Design:float glass is popular in furniture design, particularly for tabletops, shelving, and decorative partitions. Its sleek appearance enhances the aesthetic of modern furniture.

- Electronics:In electronics, clear float glass is used in screens and displays. Its transparency and durability make it suitable for protective covers in smartphones, tablets, and monitors.

- Art and Decor:Artists and designers often use float glass for various decorative applications, including glass art, mirrors, and installations. Its ability to reflect and refract light creates stunning visual effects.

To learn more about our products, please visit https://trustmyglass.com/products