1.What is porcelain slab with glass?

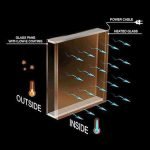

Glass ceramics are a solid material containing a glassy polycrystalline phase that is obtained by controlled nucleation and crystallization of certain basic glasses of specific composition at a certain temperature. It combines the advantages of glass and ceramics and has excellent properties such as high mechanical strength, adjustable thermal expansion, strong resistance to thermal shock, and resistance to chemical corrosion. Due to its excellent physical and chemical properties, glass ceramics are widely used in aerospace, electronics industry, biomedicine and other fields.

2.Features

- Excellent physical and chemical properties: porcelain slab with glass combine the advantages of glass and ceramics, and have excellent properties such as high mechanical strength, adjustable thermal expansion performance, strong thermal shock resistance, and chemical corrosion resistance. These properties make it have broad application prospects in aerospace, electronics industry, biomedicine and other fields.

- Good optical properties: Low-expansion and zero-expansion glass ceramics are insensitive to temperature changes and are suitable for optical fields that require dimensional stability, such as telescopes and laser housings.

- Diverse microstructures: porcelain slab with glass include nanocrystalline structures, porous film structures, coast and island structures, dendrite structures, etc., which have an important influence on their physical properties. For example, the nanocrystalline structure makes spinel and quartz solid solution glass ceramics highly transparent and can be used to make transparent tableware and accurate optical instruments.

- Designable performance: Glass ceramics have a wide range of compositions and their heat treatment process is controllable, so various types of crystals can be produced in controlled proportions, so that the properties of glass ceramics can be designed by controlling the composition and structure.

- Environmental protection and sustainability: The raw materials for manufacturing glass ceramics are very extensive, especially when producing slag glass ceramics, industrial waste can be used, which is beneficial to environmental protection and sustainable development.

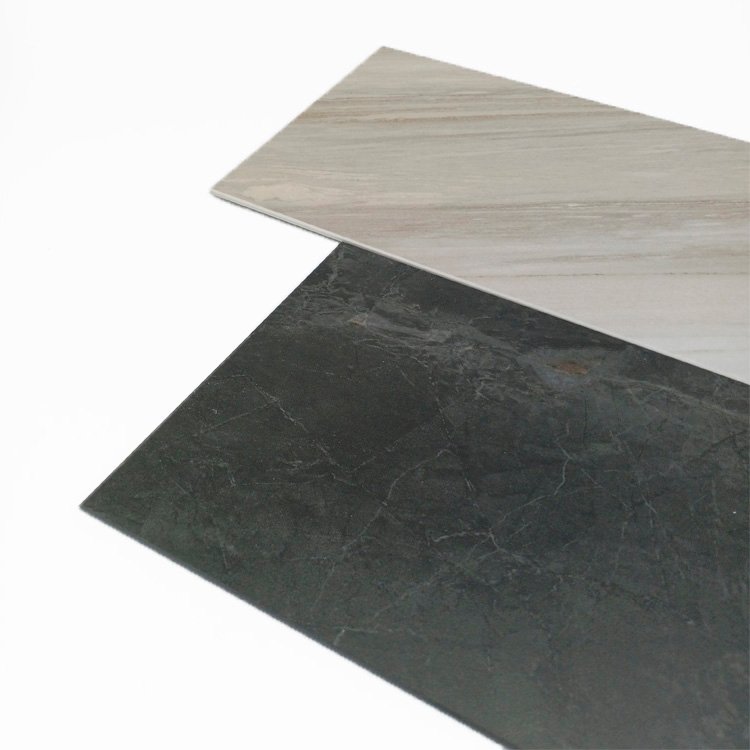

- Decorative and aesthetic: The surface of porcelain slab with glass is smooth, the texture is full of fluidity and change, the lines are natural and harmonious, and it feels warm and like jade. The surface gloss glaze is crystal clear, and the matte glaze is soft and comfortable, with high decorative value.

- Wide range of application fields: Due to its superior characteristics, porcelain slab with glass are widely used in outdoor curtain walls, interior decoration, mechanical equipment, optical instruments, aerospace and other fields.

3.Uses

- Furniture: Glass porcelain plate has all the excellent characteristics of ceramic products such as wear resistance, high strength, and anti-fouling, so it is also widely used in the field of home and furniture. For example, it can be used to make dining table panels, coffee table panels, TV cabinet panels, kitchen worktops, bathroom basin countertops, etc.

- Architectural decoration: Glass porcelain plate is widely used in the field of architectural decoration due to its excellent physical and chemical properties, such as high strength, high hardness, wear resistance, and corrosion resistance. It can be used as a decorative material for the exterior and interior walls of buildings to enhance the overall aesthetics of the building.

- Mechanical and industrial:Using the mechanical and thermal properties of glass porcelain plates such as high temperature resistance, thermal shock resistance, and adjustable thermal expansion, various materials that meet the requirements of mechanical mechanics can be manufactured.

4.Manufacturing Process

- Raw material preparation: Select the appropriate basic glass material, which is the basis of glass porcelain plate processing.

- Molding processing: Use specific molding technology to process glass raw materials into the required shape and size.

- Heat treatment and crystallization: Heat treatment of molded glass products, including two steps of heating and rapid cooling, to enhance the strength and impact resistance of glass.

- Post-processing and inspection: Conduct quality inspection, including appearance inspection, size inspection, curvature inspection, etc., to ensure that the product meets quality requirements.

- Packaging and transportation: Qualified glass porcelain plates can be packaged to prevent damage during transportation and installation.

To learn more about our products, please visit https://trustmyglass.com/products