What is Gradient hot melt glass?

Gradient hot melt glass is a specialized type of glass characterized by a smooth transition of color or opacity, often achieved through a gradient effect. This glass is typically laminated using a hot melt adhesive process, enhancing its durability and functionality.

Characteristics

- Gradient Design:The defining feature of this glass is its gradual shift in color or opacity, creating a visually striking effect. This design allows for creative applications in architecture and interior design, making it ideal for projects that require an eye-catching aesthetic.

- Hot Melt Lamination:The glass is bonded using a hot melt adhesive, which increases its strength and makes it more resistant to breakage compared to standard glass. This process also provides improved safety features, ensuring greater longevity and reliability.

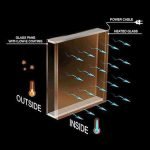

- Light Diffusion:The gradient effect can soften and diffuse light, creating a pleasant ambiance in spaces. It can reduce glare while still allowing natural light to filter through, similar to the effects seen in blended tint glass.

- Customizable:Gradient glass can be tailored to specific design requirements, allowing for unique combinations of colors and opacities to suit individual projects. This adaptability is essential for achieving desired visual impacts.

- Durability:The lamination process not only enhances the glass’s strength but also provides resistance to impact, making it suitable for high-traffic areas, akin to the robustness found in laminated glass products.

Applications

- Architectural Facades:Used in modern building designs, gradient glass can create visually appealing facades that change appearance with different angles of light, contributing to the dynamic look of architectural glass.

- Interior Partitions:Ideal for office spaces, it allows for light transmission while maintaining privacy and aesthetic appeal, similar to other transitional glass options.

- Shower Enclosures:Frequently utilized in bathrooms, gradient glass offers a stylish solution for shower doors, providing privacy without sacrificing light, much like frosted glass alternatives.

- Decorative Wall Panels:Employed in feature walls, gradient glass adds depth and interest to interior spaces, enhancing overall design with its unique visual characteristics.

- Furniture Design:Used in tabletops and cabinetry, the gradient effect can add a distinctive touch to home or office furnishings, embodying the modern appeal of ombre glass styles.

Benefits

- Aesthetic Appeal:The gradient design adds a modern and artistic element to spaces, making it a popular choice for contemporary design environments.

- Versatility:Suitable for a range of applications, from residential to commercial, gradient glass can adapt to various design styles, enhancing both functionality and beauty.

- Safety and Strength:The hot melt lamination process ensures that the glass is durable and minimizes the risk of injury from breakage, promoting peace of mind for users.

In summary, gradient hot melt glass combines beauty with practicality, making it an excellent choice for innovative architectural and design projects. Its versatility and unique aesthetic qualities continue to entice designers and architects seeking to elevate their work.

To learn more about our products, please visit https://trustmyglass.com/products