what is 3mm 4mm clear float glass?

3mm and 4mm clear float glass is a flat glass produced by float process, with specific thickness and a series of excellent physical properties. The “float” in its name refers to the glass liquid floating on the surface of molten metal (usually tin), which is obtained after annealing, cutting and assembly.

Key Features of clear float glass:

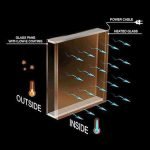

- High light transmittance: Despite being called “plain white”, 3mm and 4mm float glass still have high light transmittance and can provide a clear view. This is especially important for building doors and windows or interior partitions that require good lighting.

- Soft light: Thinner glass will have softer light when transmitting light, which will not be too glaring, which helps to create a comfortable indoor environment.

- Smooth surface: The float process makes the surface of these two glasses very flat, with almost no ripples or flaws. This is very important for applications that require high-precision planes, such as mirror making, optical instruments and other fields.

- Easy to process: The flat surface also makes these two glasses easier to cut, drill and edge grind, meeting various customized needs.

- Good weather resistance: Both 3mm and 4mm plain white float glass have good weather resistance and can maintain stable performance under various climatic conditions. They are not easily deformed or damaged due to temperature changes and are suitable for outdoor use.

Applications of clear float glass:

-

-

- Flat and smooth surface: Since float glass is formed in a molten tin bath by gravity and surface tension, its upper and lower surfaces are very flat and smooth. This feature makes float glass perform well in decorative and optical applications.

- Uniform thickness: The thickness of float glass is very precisely controlled, usually with an error of less than a few microns. This uniformity not only improves the beauty of the glass, but also enhances its structural stability.

- High transparency: The transparency of float glass is very high, reaching more than 90%. This makes it very suitable for applications that require high light transmittance, such as windows, display cabinets, optical instruments, etc.

- Good optical properties: The refractive index and reflectivity of float glass are very stable, which makes it widely used in the manufacture of optical instruments and displays.

- Pure and free of impurities: Float glass uses high-quality ore quartz sand as raw material, and the impurity content is strictly controlled during the production process, so the produced glass is pure and colorless, without glass boils, bubbles, etc.

- Tight structure: The structure of float glass is very tight, which gives it good mechanical strength and durability. At the same thickness, float glass is heavier and stronger than flat glass.

- Easy to process: As float glass has a flat and smooth surface and uniform thickness, it is very easy to cut, grind, drill and other processing.

- Wide range of applications: Float glass is widely used in building doors and windows, mirror making, automobile windshields, scanners, various deep-processed glass, solar photovoltaic curtain walls and other fields due to its excellent performance.

-

To learn more about our products, please visit https://trustmyglass.com/products