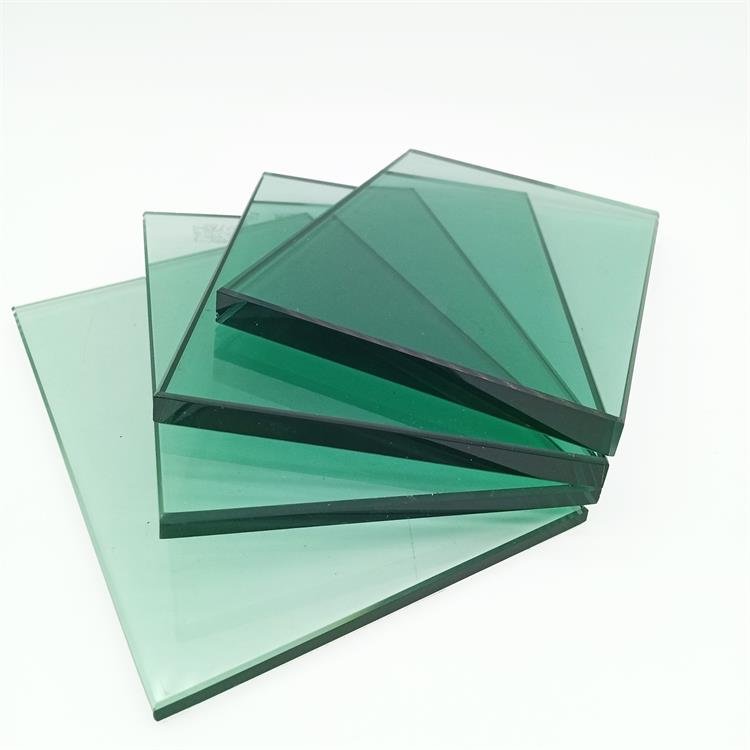

What is F green tinted float glass?

F green tinted float glass is a type of flat glass made by adding specific colorants to glass raw materials to give the glass itself a color. It is made in a tin bath with protective gases (such as nitrogen and hydrogen). Molten glass flows continuously from the tank kiln and floats on the surface of the relatively dense tin liquid. Under the action of gravity and surface tension, the glass liquid spreads and flattens on the tin liquid surface, forming a flat upper and lower surface. After hardening and cooling, it is led to the transition roller table to finally obtain a flat glass product. For F green tinted float glass, its uniqueness lies in the addition of specific colorants during the production process, which makes the glass appear green.

Key Characteristics:

- Body coloring: Advanced technology ensures uniform color distribution and long-term stability, avoiding the fading and wear problems that may be caused by traditional surface coatings.

- Excellent optical properties: Due to the special production process, green float glass has excellent optical properties, including high transparency and low light distortion rate. This allows it to maintain good lighting effects while ensuring privacy.

- Tight structure: The structure of green float glass is tight, the physical properties are more stable, and it is not easily affected by the external environment. This feature allows it to maintain a long service life in various applications.

- Flat and smooth surface: The surface of green float glass is particularly flat and smooth, without deformation such as water ripples, which is more visually beautiful and easy to clean and maintain.

- Uniform thickness: The thickness of F green tinted float glass is very uniform, which helps to improve its overall stability and durability.

- Wide range of application fields: Due to its unique color and excellent physical properties, F green tinted float glass is widely used in many fields such as construction, decoration, automobile manufacturing, and electronics industry. For example, in the construction field, it can be used for exterior walls, curtain walls.

- windows and other parts; in the decoration field, it can be used to make partitions, screens, etc.; in the automobile manufacturing field, it can be used for windshields and car windows.

applications

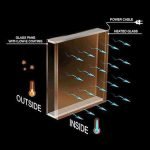

- Building field: Green float glass is often used in the exterior walls, curtain walls and windows of high-end buildings due to its excellent physical properties and unique color, improving the lighting effect and aesthetics, while enhancing the sound insulation and thermal insulation performance.

- Automobile manufacturing field: Green float glass is widely used in car windshields and windows due to its high transparency and impact resistance, improving the driver’s field of vision and driving safety.

- Electronic industry field: Green float glass is often used in electronic product window materials and insulating materials in the electronics industry due to its high transparency, chemical stability and insulation performance.

- Other fields: Green float glass is also used in display cabinets, windows and other display equipment, as well as artworks and decorations to enhance the display effect and aesthetics.

To learn more about our products, please visit https://trustmyglass.com/products

Summary

In short, F green tinted float glass, with its unique charm, not only promotes the development of modern industry, but also profoundly affects our daily lifestyle. When choosing to use it, we encourage you to carefully select the appropriate type and specifications according to specific application scenarios and functional requirements to give full play to its advantages and create a better, more efficient and sustainable future.