What is China Standard High-Strength GA 164-2005 bulletproof glass?

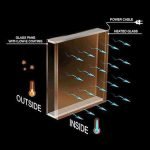

China Standard High Strength GA 164-2005 bulletproof glass is a special type of safety glass designed to withstand gunfire and explosions. This glass is usually composed of multiple layers of glass and polymer layers alternating to provide additional strength and toughness, with high security and high transparency.

Key Features of bulletproof glass:

- Safety: When a strong impact occurs, the fragments of bulletproof glass will be stuck by the organic film, reducing the risk of splashing and injuring people. At the same time, its three-layer structural design can absorb and disperse the impact force, further improving safety.

- Adhesion: The multi-layer structure of bulletproof glass is tightly bonded by special adhesives to ensure that it remains intact when subjected to strong impacts and avoids shattering into sharp fragments.

- Strong impact resistance: Bulletproof glass is designed with a multi-layer structure, with each layer made of high-strength materials such as polycarbonate or toughened glass, which have excellent impact and compression resistance. This structure enables bulletproof glass to withstand the impact of high-speed flying objects and is not easily penetrated by warheads.

- High transparency: Despite its high security, GA 164-2005 bulletproof glass still maintains good transparency and does not affect the line of sight.

- Diverse surface treatments: It can be subjected to a variety of surface treatments such as frosting and large ribs to meet different decorative needs.

- Sound insulation and heat insulation: Bulletproof glass can not only block the spread and interference of noise, but also reduce the influence of external temperature, and has good sound insulation and heat insulation effects.

- Strong weather resistance: High-quality bulletproof glass materials and processing technology enable it to effectively resist high heat and high humidity environments, and is suitable for various climatic conditions.

- Anti-aging performance: It can still maintain good physical and chemical properties after long-term use and is not easy to age.

- Easy to clean and maintain: The surface is smooth, easy to clean, and the maintenance cost is low.

- Compliance with Chinese national standards: GA 164-2005 is China’s national standard for bullet-proof glass, which stipulates the technical requirements, test methods, inspection rules and marking, packaging, transportation and storage of bullet-proof glass.

- International certification: Some products may also comply with international standards, such as the European EN 1063 standard and the American UL 752 standard, ensuring their global recognition.

- Reliable quality: After strict quality control and testing, each batch of products is ensured to meet high standards of safety performance.

- Fortified Glass:The term GA 164-2005 fortified glass indicates that the product is specifically strengthened against ballistic threats.

- High-Performance Bulletproof Glass:Referring to its superior capabilities, high-performance bulletproof glass (GA 164-2005) is designed for maximum effectiveness against projectiles.

- Enhanced Protection Glass:This glass provides GA 164-2005 enhanced protection glass, making it suitable for high-risk environments.

- Transparent Armor:Sometimes referred to as GA 164-2005 transparent armor, this product combines visibility with protection.

To learn more about our products, please visit https://trustmyglass.com/products

Applications of bulletproof glass

- Armored vehicles: The observation windows and cockpit covers of military equipment such as tanks and armored vehicles are often made of bulletproof glass to protect the occupants from enemy fire.

- Ships and submarines: Bulletproof glass is also used in the portholes, command towers and other parts of ships and submarines to ensure adequate protection in combat.

- Military aircraft: The cockpit covers and portholes of aircraft such as fighter jets, attack aircraft, and bombers are made of bulletproof glass to prevent damage during air combat or ground attacks.

- Civilian aircraft: Although civil aircraft are less likely to face direct threats of shooting, bulletproof glass is also used to improve safety in certain high-risk areas or specific missions.

- High-end luxury cars: Models of brands such as Rolls-Royce and Bentley are often equipped with bulletproof glass in their cockpits to improve the safety of passengers.

- Public buildings: In some public buildings with high security requirements, such as government buildings, embassies, etc., bulletproof glass is also used to improve the overall protection level.

- Display cabinets: Display cabinets for valuable items such as gold, silver, and jewelry, mostly in shopping malls, to protect the safety of goods from being stolen.