What is Recuttable ceramic glass?

- As an advanced engineering material that combines the properties of glass and ceramics, re-cuttable ceramic glass has demonstrated its unique value and application potential in a variety of industries. Will have a wide range of application prospects in a number of fields With the advancement of materials science and the continuous development of technology, it is expected that re-cuttable ceramic glass will be applied in more fields and continue to promote the innovation and development of related industries.

Characteristics of recuttable ceramic glass:

- Weldability with metal: Because from the beginning of glass melting, re-cuttable ceramic glass in the molten state can “wet” other materials, so it can be used in a relatively simple way to combine it with metal.

- Heat and chemical resistance: Recuttable ceramic glass has good resistance to most chemicals, making it suitable for applications in the chemical and environmental fields.

- Simplicity of Preparation: Recuttable ceramic glass can be formed into a variety of complex shapes utilizing the entire glass manufacturing process.

- Designability of properties: By controlling the heat treatment process and composition, the properties of re-cuttable ceramic glass can be designed by controlling the composition and structure.

- Dimensional stability: Compared to traditional ceramics, re-cuttable ceramic glass has a small and controlled volume change during drying or firing, helping to maintain the dimensional accuracy of the product.

Applications of recuttable ceramic glass:

- Aerospace: In aerospace, re-cuttable ceramic glass is used to manufacture complex components in engine management systems due to its low thermal conductivity, high temperature stability and excellent electrical insulation properties. The material is also used in NASA space shuttle mounts and components in several satellite systems.

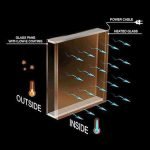

- Outdoor skylights: They have many advantages, including beauty, weather resistance, energy saving, safety, privacy protection, and easy maintenance.

- Electronics and Semiconductors: In the electronics and semiconductor industries, re-cuttable ceramic glass is often used to make precision coil holders, high-voltage insulators, and components for electronic devices because of its excellent electrical properties and high-temperature resistance.

- Medical Devices: In the medical field, re-cuttable ceramic glass is ideal for the manufacture of medical components due to its inertness, precise machinability and dimensional stability.

- Nuclear industry and high-energy physics: Recuttable ceramic glass is used in the nuclear industry as reference blocks and fixtures for generator sets, and as a key material in high-energy physics experiments.

- Military and Defense: In the military and defense fields, the high strength and chemical resistance of this material make it an important material for manufacturing high-performance weapon systems and protective equipment.

- Precision Instruments and Sensors: The high rigidity and low coefficient of thermal expansion of recuttable ceramic glass give it a significant advantage in the manufacture of precision instruments and sensors.

Benefits:

- Low manufacturing cost: the production of re-cuttable ceramic glass of a wide range of raw materials, especially the production of slag glass ceramics, industrial waste can be utilized, conducive to environmental protection and sustainable development.

- Dimensional stability: Compared with traditional ceramics, re-cuttable ceramic glass has small and controlled volume changes during drying or firing, helping to maintain the dimensional accuracy of the product.

- Electrical and optical properties: Depending on the composition, re-cuttable ceramic glass can exhibit desirable electrical and optical properties for electronic and optoelectronic applications. For example, in the electronics industry, it is used as a special substrate material for electrical components, exhibiting good thermodynamic properties and low resistivity.

- Designability of properties: By controlling the heat treatment process and composition, the properties of re-cuttable ceramic glass can be designed by controlling the composition and structure. This provides a great deal of flexibility to meet the needs of specific applications

Overall, re-cuttable ceramic glass is a high-performance advanced material that possesses not only the flexibility of glass, but also the strength and durability of ceramics, combining the best of both worlds with each other, resulting in excellent mechanical properties, heat and chemical resistance, low coefficients of thermal expansion, good electrical and optical properties, and a simple preparation process.

To learn more about our products, please visit https://trustmyglass.com/products