What is low iron float glass?

Low iron glass, also known as ultra-clear glass or high-transparency glass, is a type of ultra-clear low iron glass. Its light transmittance can be as high as 91.5% or more, and it has the characteristics of crystal clearness, high-grade elegance, so it is known as the “Crystal Prince” in the glass family. Low iron glass also has all the processability of high-quality float glass, and has excellent physical, mechanical and optical properties. It can be processed in various ways like other high-quality float glass. The unparalleled superior quality and product performance make ultra-clear glass have a broad application space and a bright market prospect.

Key Characteristics of low iron float glass:

- Excellent light transmittance: The iron content of low-iron glass is much lower than that of ordinary glass (usually less than 0.01%), so the light transmittance is higher, reaching more than 91% (the light transmittance of ordinary glass is about 83%-85%).

- Clear visual effect: The glass looks more transparent, with almost no green tint of ordinary glass, which is particularly suitable for scenes with high requirements for color reproduction.

- Supports a variety of deep processing: Low-iron glass can be tempered, laminated, coated, hot-bent and other deep processing to meet the needs of different scenes.

- Flexible customization: The size, thickness and shape can be customized according to customer needs.

Common Applications of low iron float glass:

- Building curtain walls and doors and windows: used for the exterior walls and doors and windows of high-end buildings to enhance the transparency and modernity of the buildings.

- Furniture and interior decoration: used for high-end furniture, glass stairs, partitions, etc. to enhance the sense of space.

- Display field: used for museum display cabinets, jewelry display cabinets, shopping mall windows, etc. to ensure the true color of exhibits.

- Solar energy industry: used for solar cell covers to improve the efficiency of photoelectric conversion.

Benefits of low iron float glass:

- Improve the grade of the project: The use of low-iron glass can significantly improve the grade and quality of the building or product, and increase the added value of the project.

- Expand the visual space: The transparent characteristics of low-iron glass can make the space appear more open, especially suitable for small apartments or places that need to create a sense of transparency.

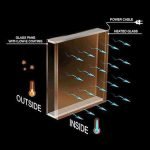

- Energy-saving effect: Low-iron glass can be combined with Low-E coating technology to further improve thermal insulation performance and reduce building energy consumption.

- Green materials: The production process of low-iron glass is more environmentally friendly and meets the needs of modern buildings for green materials.

- Flexible customization: The size, thickness and shape can be customized according to customer needs.

To learn more about our products, please visit https://trustmyglass.com/products