What is low-Iron Tempered Glass?

Low-iron tempered glass is more commonly referred to in the industry as “ultra-clear glass” or “high-transparency glass.” Its “ultra-clearness” isn’t simply a coating or dye; it’s a technological leap achieved from the source of raw materials.

Eliminating the “color” at its source: Ordinary glass exhibits a faint green tint due to the inherent iron content (primarily Fe₂O₃) in its raw materials. These iron impurities act like “green sunglasses” on the glass; though subtle, they detract from the original color of light. Low-iron glass utilizes specially purified, ultra-low-iron raw materials, significantly reducing the iron content (typically below 0.015%) and eliminating this underlying green tint.

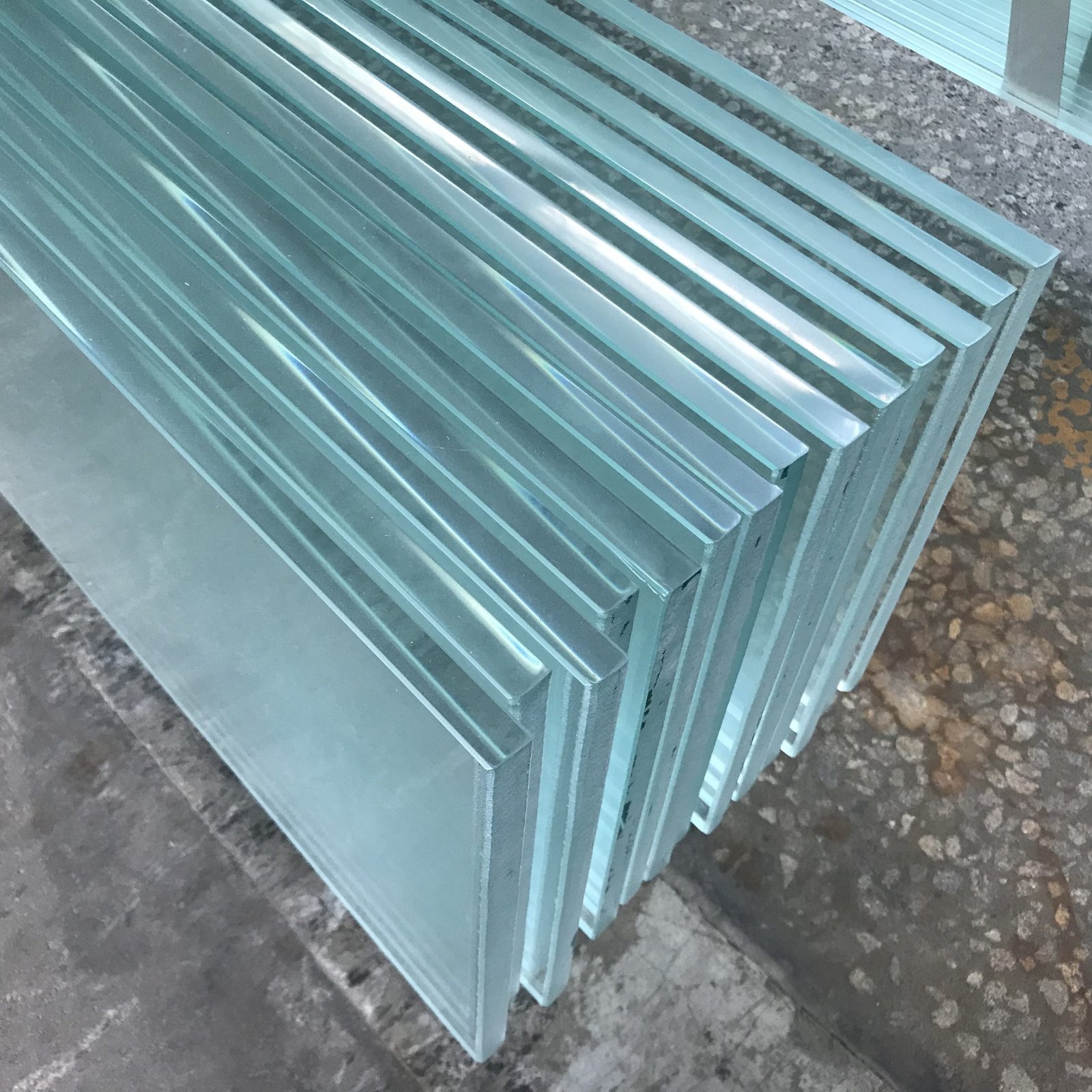

Powered by a dual process: First, it possesses the genes of low-iron glass, achieving exceptionally high original transparency. Then, it undergoes a tempering process, heating it to near its softening point and then rapidly and evenly cooling it. This creates a strong and uniform compressive stress on the glass surface, exponentially increasing its impact and thermal shock resistance.

Therefore, low-iron tempered glass is the perfect culmination of high-purity materials and cutting-edge heat treatment technology, combining unparalleled transparency with exceptional safety performance.

Advantages of Low-Iron Tempered Glass

1. Extremely Clear, True-to-Life Color Rendering

Visible light transmittance of over 91.5% surpasses the 83-85% of ordinary glass. Like a layer of nearly imperceptible pure crystal, it maximizes the amount of natural light and creates an incredibly bright and spacious space.

Key Advantage: Its near-colorless transparency faithfully reproduces the original colors of objects. For museum artwork, retail store displays, and high-end home design, this means a flawless visual presentation with zero color shift.

2. Superior Safety, Indestructible

Extremely Strong: Its bending and impact resistance are 3-5 times that of ordinary annealed glass, effectively withstanding strong winds, external impacts, and other factors.

Safety and Explosion-Proof: This is the core value of its tempered properties. When subjected to extreme, unbearable external forces, it shatters into countless tiny, blunt-angled particles, significantly reducing the risk of cuts and injuries to the human body, providing a solid guarantee of personal safety.

3. Excellent Thermal Stability

It can withstand temperature fluctuations of up to 220°C (compared to 70°C for ordinary glass), making it more resistant to thermal stress cracking (commonly known as “glass self-explosion”). This means it offers greater stability and a longer service life in environments exposed to direct sunlight and extreme heat and cold, such as glass curtain walls, shower enclosures, and oven doors.

4. Modern Aesthetics, High-End Elegance

Regardless of glass thickness, its crystal-clear, flawless texture imbues buildings and products with a pure, light, and modern aesthetic. The elimination of green edges creates a seamless, minimalist visual effect when spliced or layered over large areas, enhancing the quality and value of the overall project.

5. Versatile Base Material, Compatible with a Variety of Applications

The exceptional purity makes it an excellent base material for subsequent processing. During lamination, coating, and screen-printing processes, the finished product achieves purer, more stunning colors without the distracting green cast of the underlying layer.

Applications of low-Iron Tempered Glass

Low-iron tempered glass is used in nearly every field requiring high aesthetics and safety:

1. Architecture and Curtain Walls: High-end commercial complexes and office buildings feature glass curtain walls, skylights, guardrails, and canopies. It enhances the building’s appearance with a lighter, brighter look, optimizes indoor lighting, and reduces energy consumption.

2. High-end Retail and Display: Display windows and protective covers in luxury boutiques, jewelry stores, art galleries, and museums. It ensures 100% accurate product color reproduction, attracts customers’ attention, and enhances brand image.

3. Modern Home and Interior Design:

1) Furniture Applications: High-end coffee tables, dining tables, shelves, and cabinet doors create a sense of floating visual magic.

2) Partitions and Windows: Minimalist interior partitions, shower enclosures, balcony railings, and large sliding doors create space separation while maintaining a sense of transparency.

3) Decoration: Used as a backdrop, inlaid with paintings or photographs, they create an artistic focal point in the home.

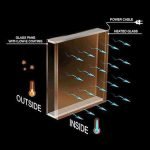

4. High-Tech Products and Appliances: Solar photovoltaic panels (which require high light transmittance to improve power generation efficiency), high-end furniture and appliance panels, laser instrument protective lenses, and substrates for fire-resistant glass.

5. Specialty Facilities: Aquarium viewing windows, high-altitude viewing platforms, stair treads, and other applications require both ultra-clear vision and high safety.

Conclusion of low-Iron Tempered Glass

In short, low-iron tempered glass is the ultimate response to quality living and uncompromising design. It transcends the traditional functional definition of glass, evolving from a simple building material to a key element that enhances the visual experience, ensures safety, and conveys brand value. Choosing it means choosing a clear, safe, and sophisticated lifestyle.

To learn more about our products, please visit https://trustmyglass.com/products